Damp- og vandtæt fugemasse

artikelnummer 120610

20 aluminum pouches per carton Water pressure test

Prior to application: Heat Flex 2000 to appox. 35-40 ° by placing it in warm water for at least 30 minutes

Tilføj til meddelelseslisteDe vigtigste oplysninger på et øjeblik

Polyolefin

.pastaagtig, stabil

Jodløs

.Fri for opløsningsmidler

.appox. + 5 ° C bis +35° C

approx. + 5 ° C bis +35° C

ca. 1,6 kg/liter hulrum

.Undersøgelsesrapport

.

MFPA Leipzig

Nr.: U / 5.1 / 08 - 043

Efter brug med universalrengøringsmiddel

.Ved 20 °C ca. 2 år

.

Preparation:

The substrate must be free from grease, tar, oil and loose particles.

Suitable substrates are: concrete, brick, mortar, plaster and all other mineral construction materials, as well as ceramics, PVC, polyethylene and polypropylene.

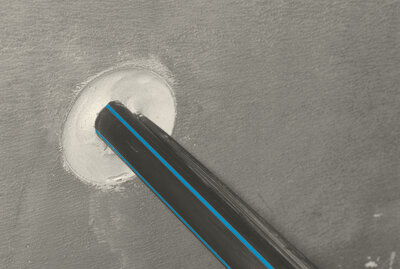

Clean the inside of the duct using a suitable brush to remove dust, sand, and any loose particles.

Prior to application, FLEX 2000 is warmed to approx. 35 - 40 °C by placing in hot water to ensure optimum consistency and workability

Installation:

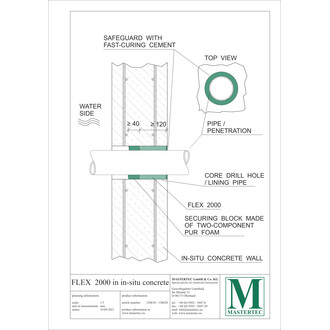

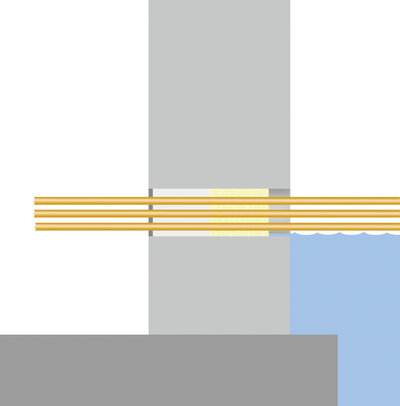

Before applying FLEX 2000, a securing block of a two-component PUR foam is applied in the duct at a depth of approx. 15 cm.

The FLEX 2000 cartridge is then inserted into the cartridge applicator and FLEX 2000 paste injected into the annular gap of the two-component securing block, starting at the back and working towards the front.The layer must be at least 12 cm thick.

After sealing cable ducts, jiggle the cables slightly and fill any cavities with FLEX 2000.

Always ensure that the cable is free of tension and strain after sealing.The sealing compound is then pressed in firmly and smoothed with a metal filler knife leaving a depression approx. 1 cm deep, which is sealed with fast-curing cement to additionally secure the mouth of the duct.

To feed through a new cable, the mortar cap is removed and the cable is pushed through the sealing compound. The duct is then re-sealed using FLEX 2000.

Inflowing water

Insert the flexible nozzle into the duct and seal it with FLEX 2000 starting from the securing block.

Fill the duct slowly spirally from the center outwards with FLEX 2000.

Fill the duct completely with FLEX 2000.

Smooth down the FLEX 2000 sealing compound with a spatula, set back approx. 1 cm.

Close the duct with fast-curing cement and smooth it flush with the surface.

Status: 23.03.2022

Tilbehør

passende tilbehør

Kontakt os

Vi svarer gerne på dine spørgsmål

engelsk

engelsk