Couvre-joints métalliques

Nous offrons des systèmes d‘étanchement des joints de construction et des joints de retrait, des éléments de coffrage et des accessoires, ainsi des joints de reprise/dilatation et notre joint de reprise/dilatation actif MASTER-Multiflex MMF.

Couvre-joints métalliques revêtus :

Ils se caractérisent par le montage qui a été vérifié et testé par la station d`essai des matériaux.

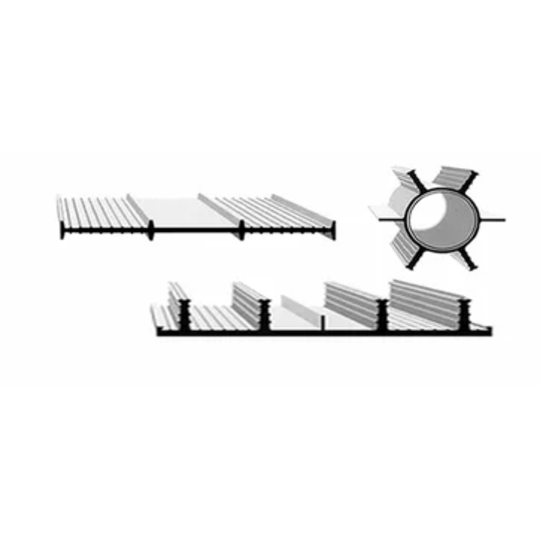

Profilés de joints de retrait :

Ils produisent volontairement un joint de retrait et l’étanchent simultanément.

Eléments de coffrage :

Ils sont prévus pour les déposes des murs et de la base.

Couvre-joints métalliques non revêtus appelés petits coils :

Ils sont montés depuis des décennies, mais leur montage n’a pas été testé.

Pour étancher les joints de construction dans la construction en béton armé. ...

Éléments de rupture pour zone angulaire SFE et FE réglable et pour le joint droit SFG. ...

Les produits de tôle d’étanchéité sont subdivisés en : - Éléments de coffrage de tôle d’étanchéité ABS. Profilés pour le béton...

Vous trouvez ci-dessous les accessoires tels que des angles de tôles d’étanchéité, des raccords de joints de reprise/dilatation, n...

Couvre-joints métalliques galvanisés et nus en rouleaux et des éléments de raccordement appropriés....

Joint de reprise/dilatation actif pour colmater les joints de construction . ...

Joints de reprise/dilatation selon nome usine pour étancher les joints de construction ...

What role do metal waterstops and shuttering elements play in reinforced concrete construction?

The white tank is a structure in which the concrete not only fulfils the load-bearing function but also acts as a seal against pressing and non-pressing water (watertight concrete). The requirements for this construction method are regulated in the WU guideline (watertight concrete structures) from the German Committee for Reinforced Concrete (DAfStb). The impermeability of the joints plays a special role in the construction of a white tank. These must be suitably sealed in accordance with the WU guideline, depending on the type of joint. Proof of usability is provided in the form of an abP (general building authority test certificate). The issue of the test certificate provides proof of functionality and defines the area of application for the respective product.

What are metal waterstops and shuttering elements used for?

Metal waterstops and coated metal sealing sheets are particularly suitable for sealing construction joints. They have proven themselves in practice for many years. The use of uncoated metal waterstops is regulated in the WU guideline.

The areas of application of coated sealing sheets are defined in the general building authority test certificates (abP). In the Waterproofing Directive, AbP's are required as proof of usability and are a prerequisite for use. The German Concrete and Construction Technology Association (DBV) has summarised extensive, supplementary explanations on coated metal waterstops in the leaflet "Coated metal waterstop systems".

Shuttering elements are used as so-called permanent formwork. They are used to separate concreting sections from each other. They are also sealed directly with an integrated sealing layer.

Predetermined crack profiles and elements are used to specifically create cracks (so-called "predetermined crack joints") and, if necessary, to seal them directly. These predetermined cracks in the wall or base prevent unplanned cracks in the component.

How do metal waterstops and shuttering elements work?

Our VB sealing sheets have a special adhesive coating and bond with the fresh concrete. They are integrated into the base in the area of the construction joint and seal it reliably.

Shuttering elements are used as permanent formwork and create a rough or toothed surface due to the expanded metal used. Shuttering elements with an integrated sealing layer also prevent water from penetrating these areas.

With the predetermined crack elements, the cross-section of the wall or base is weakened to such an extent that a targeted crack is created at this point in order to remove stresses from the component and thus prevent cracks in undesired areas. The cracks created in this way are sealed directly by the integrated sealing layer.

anglais

anglais