Transición de waterstop metálico a waterstop

número de artículo 070230

Accesorios para chapas sellajuntas

La conexión de la cinta de unión de la lámina de sellado es una forma sencilla, rápida y segura de conectar la lámina de sellado VB o la lámina de sellado MASTER a una cinta de construcción vertical o de junta de dilatación de forma estanca. No es necesario soldar ni vulcanizar. Adecuado para waterstops termoplásticos y elastómeros

Añadir a la lista de avisos

La información más importante de un vistazo

Placas de acero: St 37, brillante

Placas intermedias: NBR

Tornillos: galvanizados

160 mm

80 o 140 mm

ca. 3 mm / 5 mm

Informe de ensayo

MPA Braunschweig

Nº: (1201/307/18)-PAN del 23 de octubre de 2018

Hasta máx. 2 bar ( 20 m columna de agua )

2,50 kg / juego

2 piezas / 1 juego / caja

pre-montado

Placa de sellado VB

Placa de sellado MASTER

Sellado VB

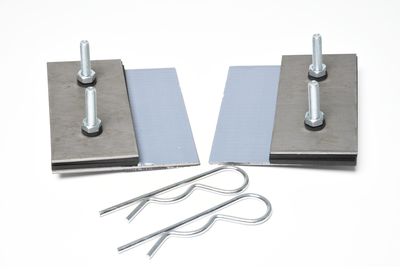

2 uds. chapa de acero, St 37, en blanco, pretaladrada

1 ud. Placa intermedia, pretaladrada

4 arandelas

2 uds. tornillos M 10, galvanizados

2 piezas de tuercas M 10, galvanizadas

1 ud. Clip de fijación

Scope of delivery:

The scope of delivery of a set includes two clamping constructions for the connection of the joint tape, which have a coated connection side for bonding to the coated joint sheet metal.

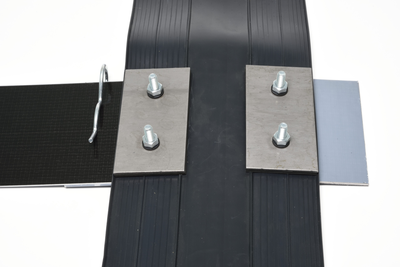

For additional protection of the transition joint with the joint sheet metal, two fixing clips are included.

Connection to the joint tape:

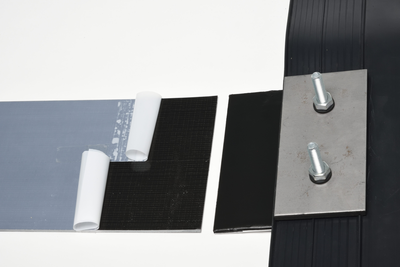

Use the supplied pre-drilled, narrower steel plate or one of the rubber plates as a template to mark the drill holes and the contact surface of the connector on the joint tape.

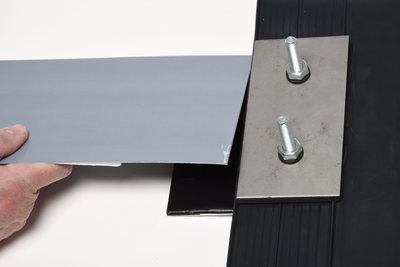

Important: The joint sheet metal/joint tape connector must be at the same height as the joint sheet metal to be connected.

Within the marked area, the water barriers or edge anchors are removed with a sharp knife.

It is not necessary to remove the much finer profiling ribs.

At the marked position, holes with a diameter of 10 mm are drilled into the joint tape.

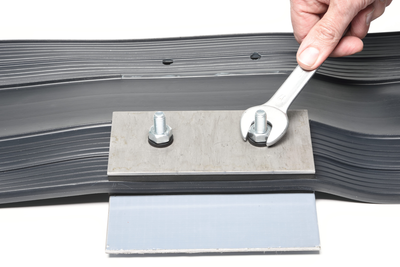

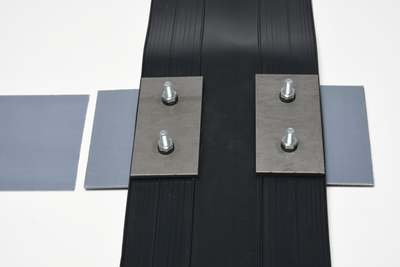

Lay the steel plates, the intermediate plates and the joint tape on top of each other as shown in the picture and the sketch below and join them together with the screws.

Important: The washers supplied must be installed between the screw head and the steel plate as well as between the nut and the steel plate.

The screws must be tightened with a torque of approx. 8-10 Nm.

When installing, make sure that the joint tape to be connected has already been concreted into the floor slab.

The joint tape must already have a horizontal water barrier in the foundation.

The joint sheet metal/joint tape connector can be used for all internal construction or expansion joint connections.

Connection of aMASTERTEC joint sheet metal to the installed joint sheet

metal/joint tape connector:

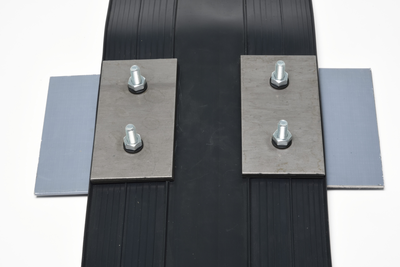

Joint sheet metal/joint tape connector mounted to the joint tape.

A water pressure-tight connection can now be made with the coated MASTERTEC joint sheet metal on the coated sides of the joint sheet metal/joint tape connector.

For this purpose, the protective foil of the coated side is completely removed.

The protective foil of the joint sheet metal to be connected must also be removed.

The joint sheet metal to be connected is now overlapped by 5 cm with the coated side (complete length) of the joint sheet metal/joint tape connector.

fixing clip must be installed to secure the joint.

The same procedure is to be carried out on the opposite side of the joint tape.

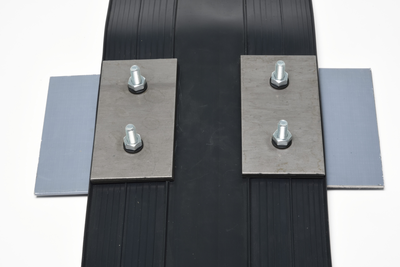

Completely assembled connection of a MASTERTEC joint sheet metal to a joint sheet metal/joint tape connector.

!!Please also observe the installation instructions of the joint sheet metal system used !!

When using our joint sheet metal MB Overlap (mineral-coated sealing sheet), always start with an adhesive surface at the joint sheet metal/joint tape connector in order to achieve a water pressure-tight connection.

Status: 23.03.2022

Contacto

Estaremos encantados de responder a sus preguntas

inglés

inglés