Listo para montar compuesto por:

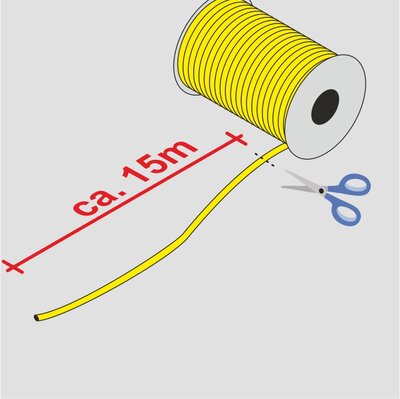

10 m de manguera de inyección MASTERTUBE incl. material de instalación

número de artículo 030055

MASTERTUBE Sistema de mangueras de inyección

El sellado de juntas de construcción de hormigón plantea grandes exigencias a la tecnología de sellado

.

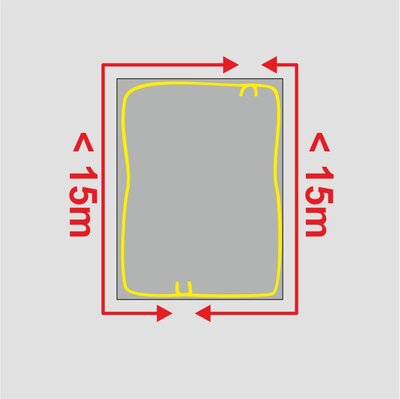

La manguera de inyección MASTERTUBE garantiza que las juntas horizontales y verticales de construcción de hormigón puedan sellarse de forma segura y permanente contra el agua a presión y sin presión

.

La información más importante de un vistazo

Manguera de PVC

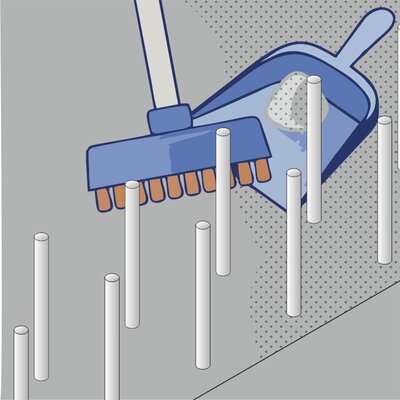

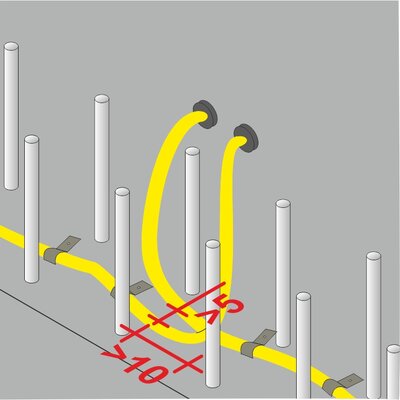

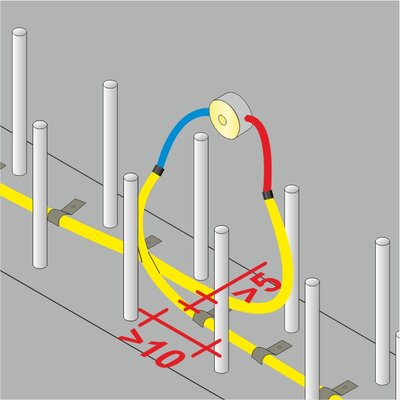

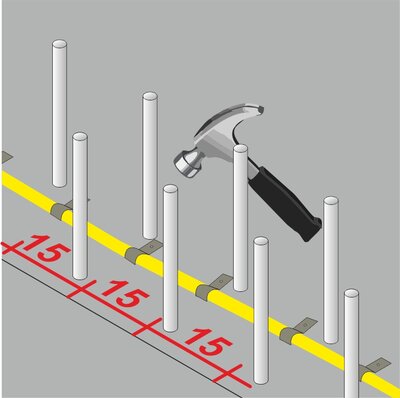

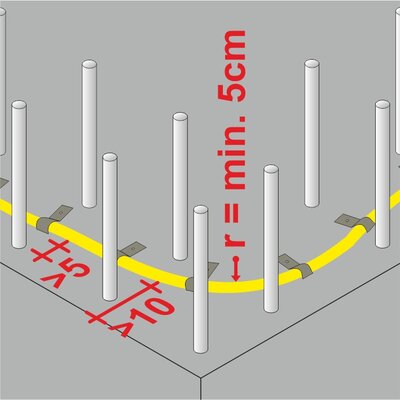

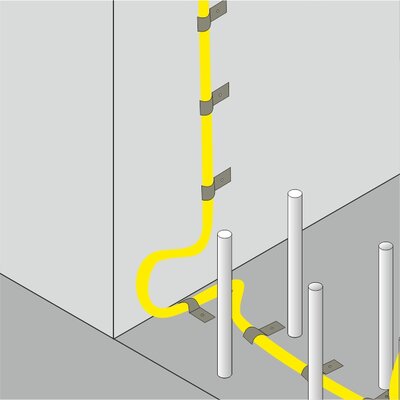

Installation of injection hose

Injection

Status: 23.03.2022

Accesorios

accesorios adecuados

Resina de poliuretano para la inyección de mangueras y la inyección de grietas ...

Productos similares

Puede encontrar productos similares aquí.

El sellado de juntas de construcción de hormigón plantea grandes exigencias a la tecnología de sellado . La manguera de inyección ...

Contacto

Estaremos encantados de responder a sus preguntas

inglés

inglés