ready for use, consisting of:

10 m MASTERTUBE injection hose and accessoires

article number 030055

MASTERTUBE Injection hose systems

High demands are placed on the technology used to seal concrete construction joints.

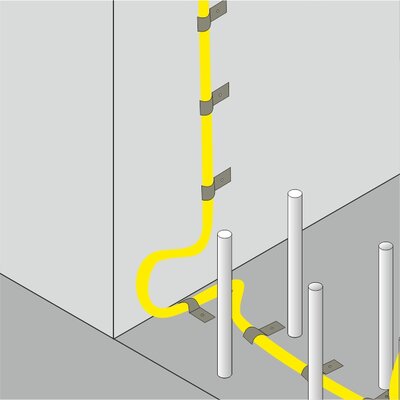

The MASTERTUBE injection hose ensures reliable and permanent sealing of horizontal and

vertical concrete construction joints against pressurised and non-pressurised water.

bag contains:

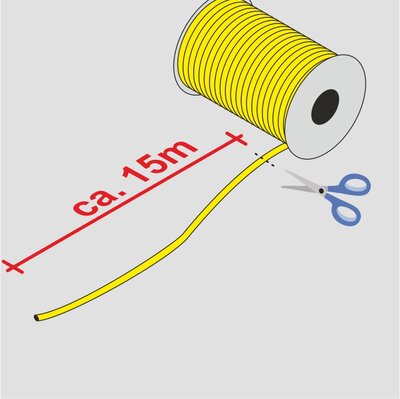

10 m MASTERTUBE YELLOW injection hose

2 fastening packers

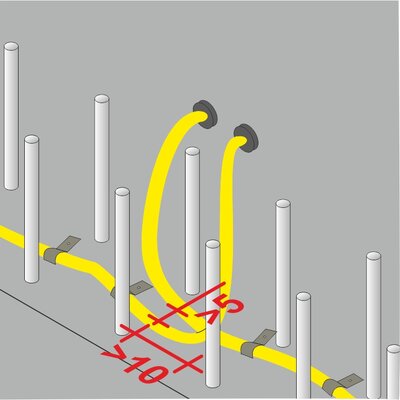

100 plastic fastening clips Type B

2 hose connectors

The most important information at a glance

PVC hose

10 m MASTERTUBE YELLOW injection hose

2 fastening packers

100 plastic fastening clips Type B

2 hose connectors

original packaging in a dry place out of direct sunlight.

landfill sites, taking into account the

local waste disposal regulations.

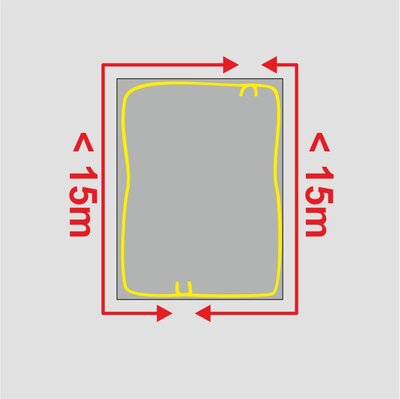

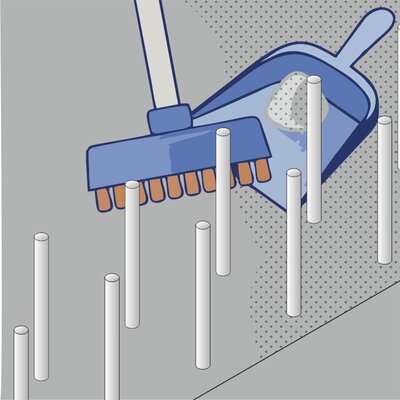

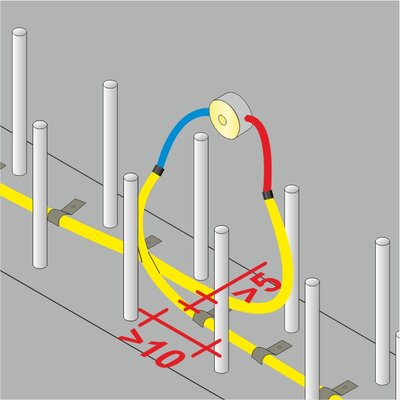

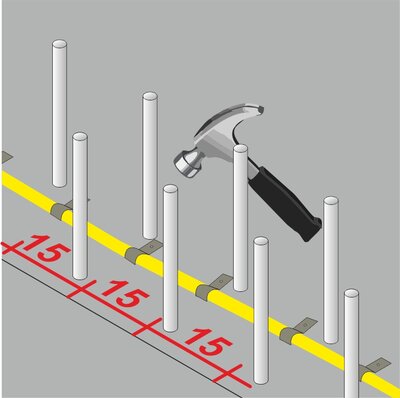

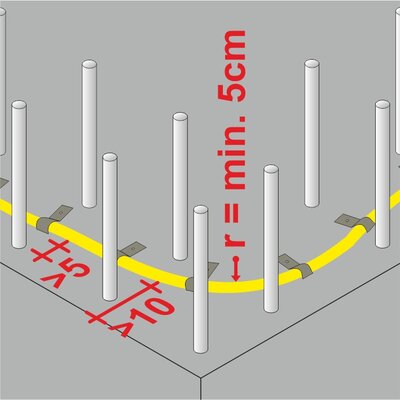

Installation of injection hose

Injection

Status: 23.03.2022

Accessories

suitable accessories

polyurethane resin for hose and crack injection PU-resin has low viscosity and provides a permanently elastic seal, long process...

Similar products

You can find similar products here.

High demands are placed on the technology used to seal concrete construction joints.The MASTERTUBE injection hose ensures reliable...

Contact us

We are happy to answer your questions

English

English