fully coated on both sides, with fixing angle

article number 070468

The most important information at a glance

St 37, galvanized

special coating: polymer resin

fabric-reinforced

20,00 m

160 mm

approx. 0,6mm

approx. 0,15 mm

approx. 0,9 mm

Test report PB 5.1/14-423-3

MFPA Leipzig

yes

Utility class A for the wear classes 1 and 2 in accordance with the WU guideline

No

Yes

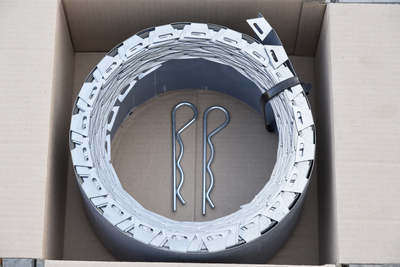

carton (40 x 40 x 20 cm)

1 roll

2 fixing clips

36 cartons per pallet

Store in undamaged and unopened

original packaging in a dry place out of direct sunlight.

Packaging

1 Role with 20 m

2 fixing clips

Remove the bottom half of the parted protective foil from the special coating.

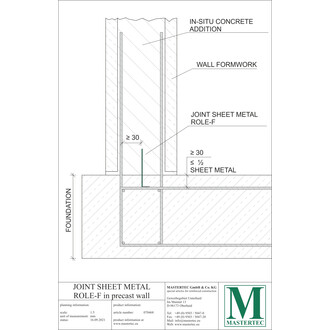

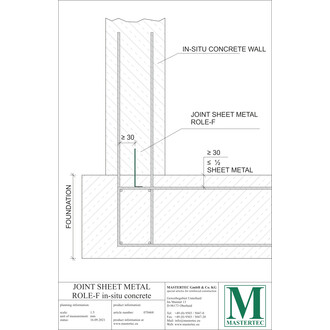

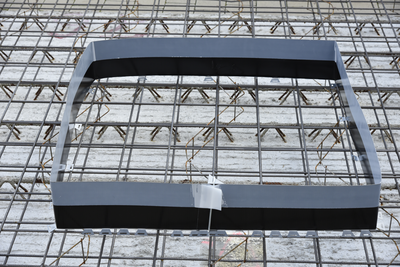

Place the Joint Sheet Metal Role-F on the top reinforcement in the center of the rising wall. Use binding wire to tie the fastening foot to the reinforced layer. The emedment depth in the concrete must be at least 3 cm and must not exceed half of the sheet height (8 cm).

By bending and crimping a festenig foot to the opposite side (approx. every 50 cm) the position of the sheet can be addtionally stabilized.

In the corner area, the sheet is bent according to the course of the corner. It is advisable here to bend over a "sharp" edge.

At transition joints, the Joint Sheet Metal Role-F must be overlapped by at least 6cm. For this purpose, the protective film is folded badk along the length of the overlap.

The overlapping surfaces are pressed together over the entire surface and secured with one of the supplied fixing clips. Ther must be no dirt on the adhesie surfaces that could impair the bonding.

The Joint Sheet Metal Role-F must form a self-contained, defect-free circuit. The upper half of the protective film must remain on the special coating until the latest possible time. The concreting of the wall base and the corresponding preparations for this must be carried out in accordance with the recognized technical regulations.

Status: 23.03.2022

Contact us

We are happy to answer your questions

English

English