fully coated on both sides

article number 070464

packed in carton

width 120 mm

thickness 0,9 mm

incl. 30 mounting brackets and

incl. 2 fixing clips

water pressure test by MFPA Leipzig

groundwater neutral

The most important information at a glance

St 37, galvanized

special coating: polymer resin

fabric-reinforced

20 m

120 mm

approx. 0,15 mm

approx. 0,9 mm

Test report PB 5.1/15-146-2

MFPA Leipzig

yes

Utility class A for the wear classes 1 and

2 in accordance with the WU guideline

No

Yes

carton (40 x 40 x 20 cm)

1 roll

2 fixing clips

30 mounting brackets

48 cartons per pallet

original packaging in a dry place out of direct sunlight.

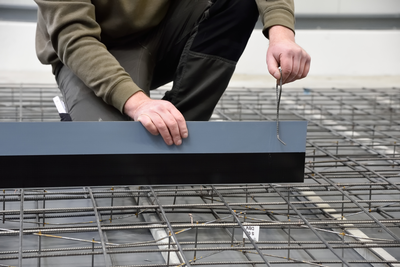

Remove the bottom half of the parted protective foil from the special coating.

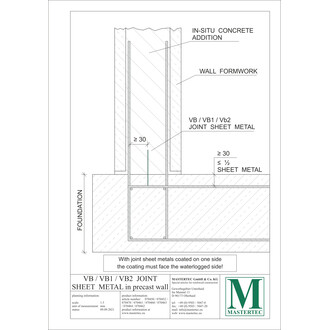

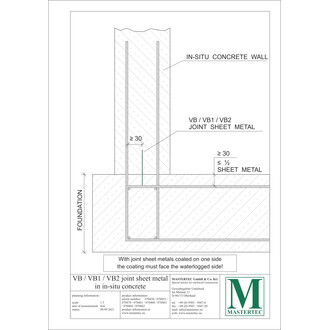

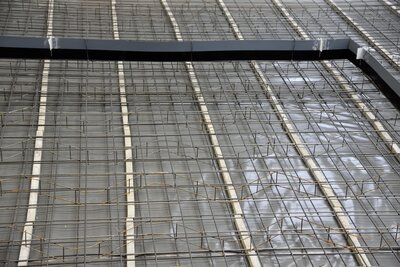

Place the VB joint sheet metal in the centre of the rising wall on top of the upper reinforcement layer.

Push the mounting brackets with a maximum distance of 70 cm over the sheet metal and fix them to the upper reinforcement layer with binding wire.

The embedment depth in the concrete must be at least 3 cm and must not be more than half the height of the sheet metal.

PLEASE NOTE!! The coating of the joint sheet metal VB1 must face the waterlogged side!

The VB joint sheet metal must overlap by at least 6 cm in the area of the joint, in the straight sections and also in the corner area.

To do so, the upper protective foil must be turned back in the area subsequently to be joined.

Overlap the VB joint sheet metal by at least 6 cm and press the two ends firmly together.

The joint must be glued over its full height and entire surface to prevent subsequent water permeation.

There must be no contamination on the adhesive surfaces that could interfere with bonding.

Secure the joint with one of the fixing clips provided and fold the protective foil back onto the special coating.

Prepared joints in the straight sections as well as the corner area.

Once the foundation slab has been concreted, and before the wall formwork is closed or the double wall elements have been set up, the remaining protective foil must be removed.

The concreting of the wall base and corresponding preparations must be carried out in accordance with the established technical standards.

Status: 23.03.2022

Contact us

We are happy to answer your questions

English

English